Setting up, pouring and finishing a concrete floor doesn’t just happen. It takes some careful planning. And the more complicated the floor, the more planning. Factory and warehouse floors with high F numbers, steel reinforcing and toppings are a good example.

The following 24 steps to pouring successful floors are excerpted with permission from the January 2000 edition of Concrete International, the magazine of the American Concrete Institute.

- Conduct a preconstruction meeting to set up a well-executed installation and placement plan for slab-on-grade.

- Facilitate on-site communication between suppliers and contractors with continuous site visits by the consultants and the inspection/testing service.

- Select an experienced flooring contractor with a proven SFRC floor construction record.

- Require adherence to specified tolerances and reject defective products.

- Reduce cost without compromising quality and safety by improving the construction schedule.

- Insist on a clean work site with well-organized storage areas.

- Retain trained and responsive supervisors and coordinators and insist on field supervision by the general contractor.

- Coordinate on-time delivery of materials.

- Review joint details, placement size, and sequence of activities prior to scheduling each placement. Correct interferences and resolve site constraints before placing concrete.

- Optimize the concrete mixture on a quantitative basis to improve construction productivity as well as reduce cosUse 1½” (40mm) maximum coarse aggregate size and a 50-to-50 ratio of 1½” and 3/8″ (10mm) blend of coarse aggregates.

- Strive to obtain a consistent water-cementitious materials ratio (w/cm) of 0.45 plus or minus 0.02.

- Attempt to keep cement content consistent to reduce further adjustment to sand proportions.

- Achieve surface durability using trap rock, liquid sealer/hardener.

- Use SFRC to achieve higher concrete tensile strength, toughness, and ductility.

- Use the pinwheel contraction joint pattern to isolate columns and control irregular shrinkage cracks.

- Design fewer construction joints to reduce construction costs and to control curling at joints.

- Use a ½” (13mm) choker coarse lime screening as a slip-sheet between the slab-on-grade and the subgrade.

- Design using compactable granular subgrade material and appropriate thickness.

- Use 4000 psi (30 Mpa) concrete with minimum cement content of 560 1b/yd3 (330kg/m3), a 6-bag mix.

- Do not use fly ash in lieu of portland cement content in floor slab application.

- Maintain a smooth, well-graded and compacted subgrade and subbase surface.

- Allow sufficient mixing time between high-range, water-reducing admixture and steel fiber.

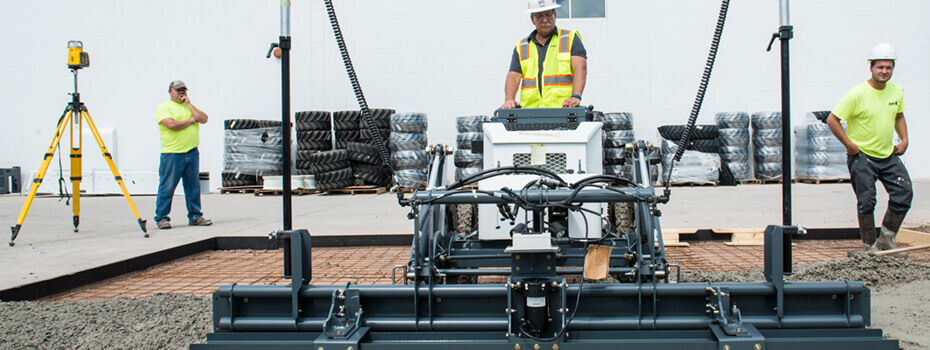

- Use a Laser Screed to obtain a flat and fiber-free surface, reduce the number of placements, and place larger areas.

- Insist on skilled operators and tradesmen utilizing new tools and maintained equipment.